Our vast experience covers all market sectors from new-build structures, structural refurbishment of existing buildings to the complex and challenging.

Our vast experience covers all market sectors from new-build structures, structural refurbishment of existing buildings to the complex and challenging.

Based on our extensive project experience, we can provide budgetary estimates or in-depth assessments to meet your specific project needs.

Our ultimate objective is to reduce client risks, optimise project design, ensure transparency, and deliver the most cost-effective options. For direct communication with the Head of our Estimating department, please contact Martin Camm at martin.camm@metstructures.uk.com

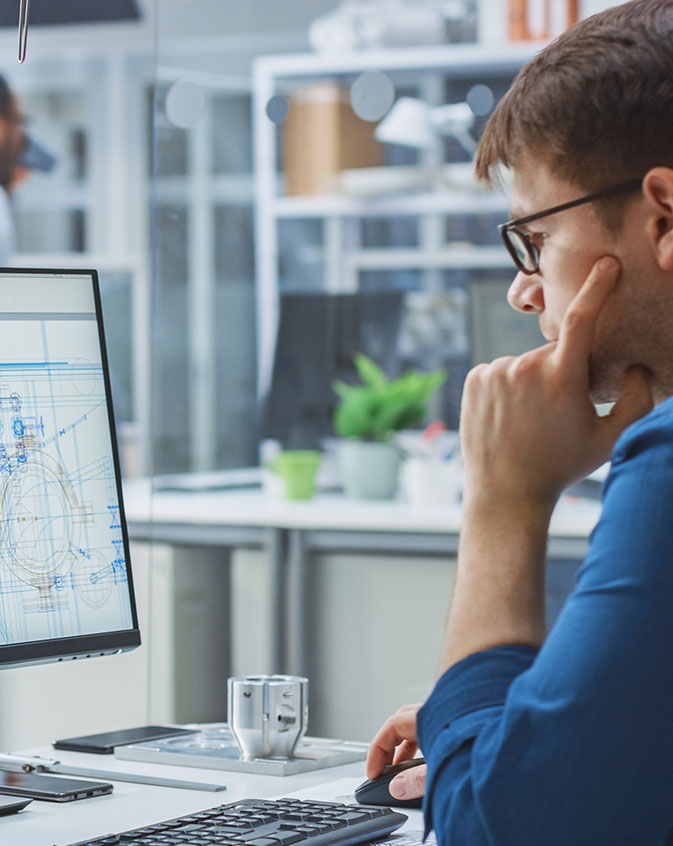

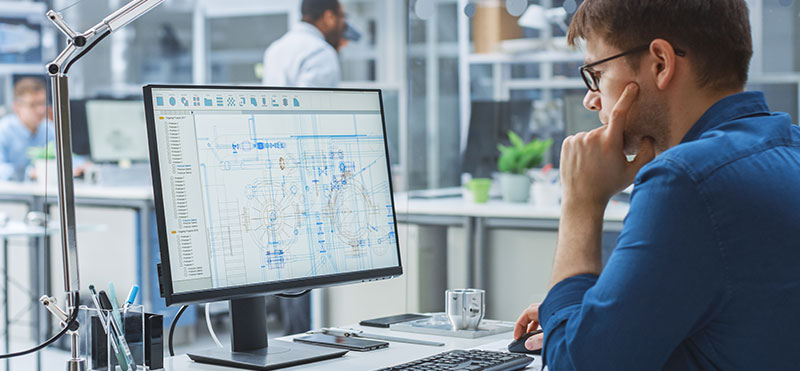

One of MetStructures greatest strengths in providing comprehensive design and detailing capabilities, giving clients a seamless, all-in-one solution for their project build.

By integrating innovative strategies for cost reduction and procurement without compromising quality or effectiveness, MetStructures ensure a highly efficient and cost-effective project delivery. Moreover, our expertise in streamlining material acquisition enables our designers to optimise designs and minimise client expenses, ensuring a successful and budget-conscious project is delivered.

At MetStructures, our Drawing office utilises the most up to date advanced AutoCAD and Tekla 3D BIM software to model intricate 3D structures seamlessly integrated with a CNC production facility. This streamlines the design, procurement, and production process, fostering real-time communication and collaborative phased manufacturing, optimising our just-in-time system to provide one efficient, effective, and budget-conscious solution.

With MetStructures’ one-stop-shop approach, clients can rest assured that their project will be efficiently designed and constructed while staying within their financial boundaries.

Our extensive in-house experience allows us to provide specialised expertise in various sectors of structural steelwork within the UK.

These encompass:

Our manufacturing capabilities are unmatched boasting top-tier fabrication facilities, backed with comprehensive stockyards, advanced in-line cutting, precise fabrication welding and painting processes complemented by some of the industry’s most extensive finished goods storage areas.

Our firm belief in the capabilities of our people drives us to continuously invest in their development.

The exceptional work we achieve is a direct result of the unwavering dedication and extensive skills possessed by our manufacturing experts.

Their expertise ensures the efficient effective and budget-conscious completion of complex briefs and large-scale undertakings enabling us to remain at the forefront of the industry and consistently surpass expectations.

MetStructures is highly adept at the efficient handling and management of fabricated steelwork utilising a continuous flow system for shot-blasting and painting. We ensure that all our products meet the rigorous standards of CE manufacturing compliance.

Following the treatment, to ensure optimal quality all products are carefully allocated to specific drying areas prior to their transportation to site. With our expertise we handle and store large volumes of intumescent and other specialised coatings seamlessly, and throughout the whole process, all our operations are subject to rigorous quality control measures.

Safety is our utmost priority, and we strive to work with suppliers who share the same commitment, ensuring seamless project implementation.

MetStructures collaborates with WS Transportation (WST) as the primary haulage partner for the transportation of the majority of our steel products who use the state-of-the-art up-to-date equipment, including new trailers, specialised trailer safe systems, exclusion zone barriers, cycle-aware cameras, and audible warning features specifically designed for city centre deliveries.

For the more unique or unconventional loads and deliveries, we rely on fully accredited and experienced haulage operators, complemented by escort vehicles when necessary, to ensure the highest level of safety and security for all transportation requirements.

At MetStructures, safety is the cornerstone of our operations. We prioritise the well-being of our personnel on all our project sites. This begins with a rigorous selection process, ensuring that we employ qualified individuals who possess the necessary expertise and commitment to safety. To further support their professional growth and maintain our high standards, we invest in comprehensive training and development programs.

In our pursuit of excellence, we closely collaborate with reputable equipment manufacturers. This collaboration allows us to equip our workforce with the most advanced and appropriate tools and machinery, ensuring both efficiency and safety throughout our construction processes.

One of the cornerstones of our safety approach is the implementation of our innovative MetSafe systems. These systems encompass a range of cutting-edge safety solutions that elevate the protection of our workers. The ‘MetSafe Edge Protection System’ provides a reliable handrail solution, minimizing the risk of falls at elevated worksites. Meanwhile, the ‘MetSafe Off-load System’ is specifically designed for the secure loading and unloading of steelwork, preventing accidents during material handling. Additionally, we employ a tool-tethering system, which further enhances our safety performance, reducing the risk of dropped objects and potential hazards.

To ensure that safety standards are consistently upheld, we conduct regular monitoring and audits across all our project sites. This proactive approach helps us identify and address potential safety concerns before they become serious issues, reaffirming our commitment to maintaining a safe working environment for our valued workforce.

The HSEQ Leadership Team made of Directors, Managers and employee representatives actively promotes and fosters positive Health and Safety Management through all levels of the business to make certain that objectives are clearly communicated, understood and achieved.

Implementation of current and new legislation with arrangements instated to monitor and measure to ensure continual compliance.

Site Managers conduct a Weekly Site Safety Inspection Report. These are submitted to the MetStructures management and the Health and Safety Consultant reviews each inspection report and follows up on any identified actions.

One of the key ways we promote sustainability is through our simultaneous on-site/off-site construction approach. This innovative method allows us to fabricate and assemble components both at our manufacturing facility and on the construction site concurrently. This not only reduces construction time but also minimizes waste generation and noise pollution in the local area. As a result our projects have a smaller environmental footprint compared to traditional building methods.

From the very beginning we focus on handling raw materials with utmost efficiency and effectiveness ensuring that waste is minimized throughout the manufacturing process. Our design philosophy centres on utilizing materials in their supplied sizes which significantly reduces waste even before production begins. This commitment to sustainable material usage aligns with our vision of promoting a circular economy and reducing our overall impact on the environment.

To further strengthen our environmental efforts we maintain an exemplary Environmental Management System. This system ensures that our daily operations are conducted in a manner that mitigates any adverse environmental impact. Through regular monitoring assessment and improvement measures we are continuously working towards minimizing our carbon footprint conserving resources and protecting the ecosystems around our projects.

In summary MetStructures not only delivers innovative and high-quality steel structures but also serves as a trailblazer in sustainable construction practices. By embracing eco-friendly methodologies reducing waste and implementing an effective Environmental Management System we aim to lead the way towards a greener more sustainable future for the construction industry and the planet as a whole.